Views: 0 Author: Site Editor Publish Time: 2025-09-29 Origin: Site

Environmental test chambers set the baseline for product reliability — choosing the right manufacturer determines whether your tests are precise, repeatable, and compliant. Danble Instrument, a leading environmental test chamber manufacturer, has built a reputation for high-quality chambers tailored for aerospace, electronics, and new energy industries. With decades of combined R&D experience, the company delivers both standard and fully customized solutions, helping engineers achieve accurate test results while maintaining operational efficiency and regulatory compliance.

Environmental test chambers are sophisticated instruments designed to simulate real-world conditions in a controlled laboratory setting. They reproduce extreme temperatures ranging from sub-zero cold to high-heat environments, fluctuating humidity levels, thermal shocks, solar or xenon light exposure, and corrosive environments like salt fog. Benchtop units are ideal for compact, high-precision testing of small components, while walk-in chambers can accommodate full assemblies or multiple products simultaneously, allowing large-scale validation under consistent conditions.

Selecting the right manufacturer is crucial because the precision of these functions depends on meticulous engineering, advanced control systems, and consistent build quality. Even small variations in temperature uniformity or humidity control can result in test failures, product recalls, or non-compliance with regulatory standards. Manufacturers like Danble Instrument ensure that chambers are engineered with high-grade materials and optimized airflow to provide uniform environmental conditions across the chamber interior.

The repeatability of environmental testing is directly tied to manufacturing quality. High-grade stainless steel and corrosion-resistant insulation maintain thermal stability over long cycles, while precision PID controllers regulate temperature and humidity with minimal drift. Calibrated sensors with traceable accuracy enable engineers to rely on the data for regulatory compliance and product development. Selecting an experienced environmental test chamber manufacturer ensures that components — from insulation and airflow design to the refrigeration system — contribute to reproducible, high-integrity test results. Moreover, attention to mechanical tolerances and wiring standards prevents unexpected failures and extends chamber longevity.

Modern environmental test chambers integrate precision controls such as PID or cascade refrigeration systems, enabling fine regulation of temperature and humidity. Micro-step humidity control allows for gradual transitions, reducing stress on sensitive components. Thermal profiling tracks spatial temperature distribution inside the chamber, providing engineers with detailed insights for optimizing test conditions. Advanced thermal profiling can identify hotspots or airflow imbalances, which is particularly important for electronics, batteries, and precision instruments.

Leading manufacturers embed sophisticated data acquisition systems that continuously log test parameters, allowing for detailed reporting and analysis. Remote monitoring capabilities, via Ethernet or cloud platforms, enable engineers to observe tests in real time and receive instant alerts for deviations. API-enabled connectivity supports Industry 4.0 integration, making environmental chambers compatible with automated lab networks and enterprise data systems. These features enhance efficiency, reduce human error, and provide digital records essential for compliance and validation. Remote access also allows teams in multiple locations to coordinate testing without physically being in the lab.

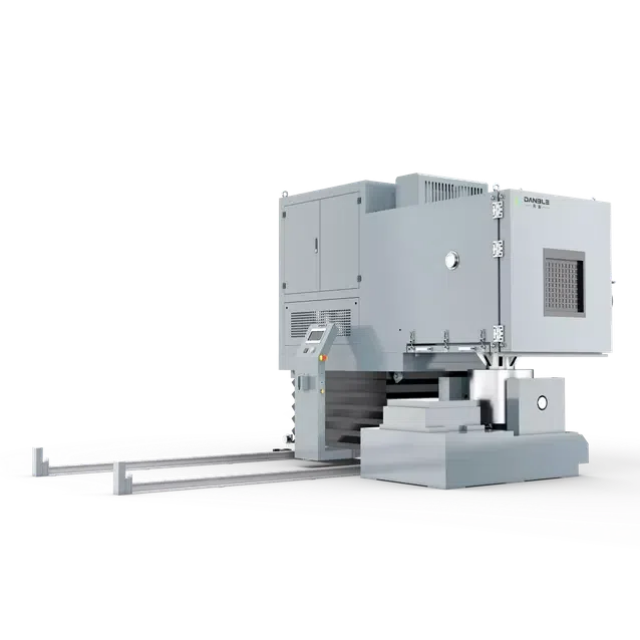

Some manufacturers offer chambers capable of combined stress testing, such as climate plus vibration or solar simulation combined with temperature and humidity cycling. Modular walk-in solutions allow for scalable, configurable chambers that adapt to changing product dimensions or test requirements. These innovations allow manufacturers to replicate complex operational environments, supporting product development across multiple industries including defense, automotive, and consumer electronics. With modular designs, maintenance and component replacement are simplified, reducing downtime and operational costs.

Procurement teams should request detailed specifications, including temperature and humidity ranges, uniformity and stability metrics, ramp rates, chamber volume, and sensor accuracy. These specifications directly affect the reliability of your tests, and only transparent manufacturers provide measured performance data under standard test conditions. It’s also helpful to compare chamber capabilities with your testing protocols to ensure the selected model meets long-term validation needs.

ISO 9001 certification indicates disciplined manufacturing practices. Evaluate whether the manufacturer maintains strict tolerances, operates dedicated test benches, and conducts pre-shipment verification. Danble Instrument subjects every chamber to rigorous internal testing before delivery, ensuring consistency and performance from day one. In addition, manufacturers that follow lean production principles can often deliver faster lead times without compromising quality.

Consider calibration services, spare parts availability, field service engineers, and remote diagnostic support. The ability to maintain and troubleshoot a chamber throughout its lifecycle is essential for uninterrupted testing. Manufacturers who offer comprehensive post-sale support reduce downtime, ensure consistent performance, and protect your investment in the long term. For example, remote diagnostics allow rapid identification of issues, preventing costly lab interruptions.

IEC 60068 standards define climatic testing procedures for temperature, humidity, and combined environmental conditions. When evaluating manufacturers, check how chambers meet relevant clauses such as temperature cycling, damp heat, or salt mist exposure. Compliance ensures that chambers deliver results consistent with international testing protocols and provides confidence for product certifications.

For defense or aerospace applications, MIL-STD-810 defines rigorous environmental test methods. Manufacturers must provide test data showing how chambers replicate shock, vibration, humidity, and temperature extremes. Mapping manufacturer specifications to MIL-STD-810 methods ensures that products meet strict operational requirements and perform reliably under demanding conditions.

Many manufacturers validate chambers using ASTM, DIN, or EN methods, which offer standardized procedures for assessing environmental performance. Reliable data from recognized standards enhances confidence in test results and helps procurement teams compare suppliers objectively. It also simplifies regulatory submissions for industries that require documented compliance.

Large walk-in chambers require careful planning for production, delivery, and installation. Lead times vary depending on model complexity, and manufacturers may offer customization to fit unique lab layouts or test requirements. Early engagement allows teams to align chamber capabilities with project timelines, minimizing disruptions. Custom options may include additional ports for instrumentation, specialized airflow configurations, or integrated lighting systems for optical testing.

Beyond purchase price, consider energy consumption, calibration intervals, consumables, and spare parts planning. Chambers with energy-efficient designs, modular consumables, and easy maintenance reduce operational costs over time. Danble Instrument focuses on energy-efficient systems that maintain precise performance while lowering long-term operating expenses. TCO assessment helps labs budget accurately and make sustainable choices without compromising testing quality.

Show me a performance report for the exact model and test profile we will use.

How do you handle sensor drift, and what calibration traceability do you offer?

What software or data formats are supported for logging and export?

Can you demonstrate chamber behavior under combined stress conditions?

What post-sale support and remote diagnostic capabilities are available?

These questions help procurement teams ensure a manufacturer can deliver repeatable, reliable results and support regulatory compliance.

Selecting the right environmental test chamber manufacturer is critical to achieving precise, repeatable, and standards-compliant test results. Danble Instrument combines robust engineering, advanced technologies, and a commitment to customer support, enabling organizations across aerospace, electronics, and energy sectors to validate their products with confidence. For detailed specifications, custom configurations, or to explore the optimal chamber for your testing requirements, contact us today to learn more about our environmental test chambers and secure your lab’s performance future.